Conveyor systems have revolutionized various industries by streamlining operations and increasing efficiency. If you’ve ever wondered about the intricacies of installing these systems, then you’re in the right place. Let’s dive into the world of conveyor systems and their installation.

Introduction: Why Conveyor Systems are Essential

Conveyor systems are the unsung heroes of the manufacturing and distribution industries. They move goods smoothly from one point to another, ensuring that products are delivered timely and efficiently. Whether it’s a simple belt conveyor in a grocery checkout line or a complex roller system in a massive warehouse, conveyors play a pivotal role in keeping operations running smoothly. Source: Conveyor Equipment Manufacturers Association (CEMA)

Types of Conveyor Systems

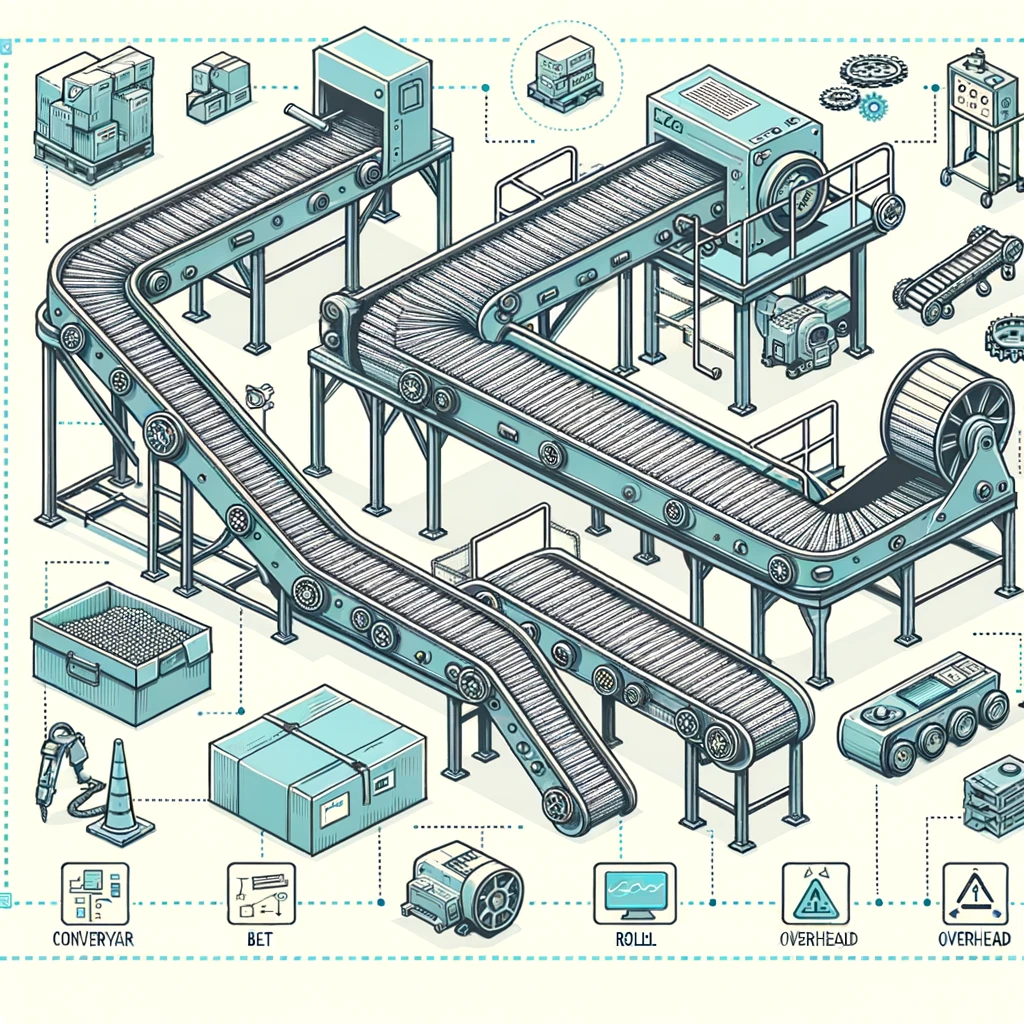

Before diving into the installation, it’s vital to understand the different types of conveyor systems:

- Belt Conveyors: These are continuous belts made of fabric, rubber, or metal, and they move products along a flat or inclined path.

- Roller Conveyors: Ideal for heavy or bulky items, these conveyors use rollers to transport products.

- Overhead Conveyors: These are used to move products overhead, freeing up floor space.

- Chain Conveyors: Made of chains, they move products along the production line.

Source: Material Handling Equipment Distributors Association (MHEDA)

Steps to Install a Conveyor System

- Planning: Begin by assessing your space and determining the type of conveyor that best suits your needs.

- Layout Design: Map out where the conveyor will be placed, ensuring there’s adequate space for operations and safety.

- Assemble Components: Start by laying out all the parts and following the manufacturer’s instructions.

- Installation: Secure all parts, ensuring they’re aligned correctly.

- Testing: Run the conveyor to ensure it operates smoothly.

Source: Occupational Safety and Health Administration (OSHA)

Common Installation Mistakes to Avoid

- Incorrect Spacing: Ensure there’s enough space between conveyors and other equipment.

- Ignoring Manufacturer’s Instructions: Always follow the provided guidelines.

- Overloading: Don’t exceed the conveyor’s weight capacity.

Source: National Safety Council (NSC)

Safety Measures During Installation

Safety should always be a priority. Here are some measures to ensure a safe installation:

- Wear Protective Gear: Always wear helmets, gloves, and safety shoes.

- Switch Off Power: Before starting the installation, ensure the power is off.

- Regular Maintenance: Once installed, regular checks and maintenance are crucial for safety.

Source: American Society of Safety Professionals (ASSP)

Installing conveyor systems can seem daunting, but with the right approach, it’s a smooth process. Remember, the key is planning, following safety guidelines, and ensuring regular maintenance. With these in place, you’re on your way to optimizing your operations.

Source: International Organization for Standardization (ISO)